Coakham Farm

Commission: Coakham Farm were keen to install a biomass system to heat 7 domestic dwellings and also a new grain drying facility. With biomass drying costing around 4pkWh compared to other grain drying options such as propane at 8pkWh, biomass was an obvious choice for this.

Boiler Type: 1 x Herz FM99 HD and 1 x Herz FM100

Fuel Type: Wood chip

Fuel Storage: Purpose built store with additional Grain Drying Facility

CO2 emission reduction: 945 tonnes

Case History: This was a two stage project. Stage one involved the installation of a 100kW boiler, fuel handling system, 2000ltr buffer tank and district heating system into a temporary plant room. This was immediately able to supply heat to the 7 domestic dwellings.

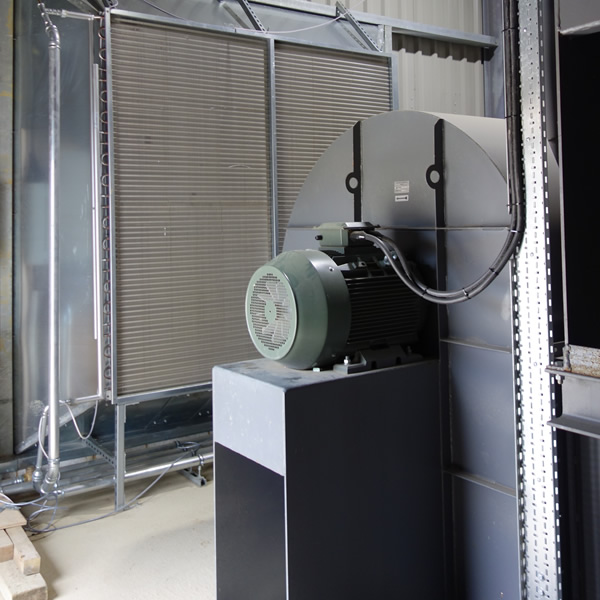

Stage two comprised of the removal and re-instatement of boiler 1 into a newly constructed permanent plant room and fuel store. At this stage, a second 99kW boiler was incorporated into the system giving sufficient capacity to include the farm’s grain drying facility. The grain dryers use two water to air exchangers supplied with heat from the biomass system, with PID control giving precise relative humidity control.

Date Completed: September 2015